What is ATEX?

ATEX Directive (Atmosphères Explosibles):

- This is a set of European Union directives for controlling explosive atmospheres. It ensures that equipment and protective systems intended for use in potentially explosive atmospheres are safe.

- The directive consists of two EU directives:

- Directive 2014/34/EU (ATEX 114): Concerning the equipment and protective systems intended for use in explosive atmospheres.

- Directive 1999/92/EC (ATEX 137): Concerning the minimum requirements for improving the health and safety protection of workers potentially at risk from explosive atmospheres.

What is IECEx?

IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres) is a global certification system that ensures the safety and reliability of equipment intended for use in hazardous areas where explosive atmospheres might occur.

Purpose:

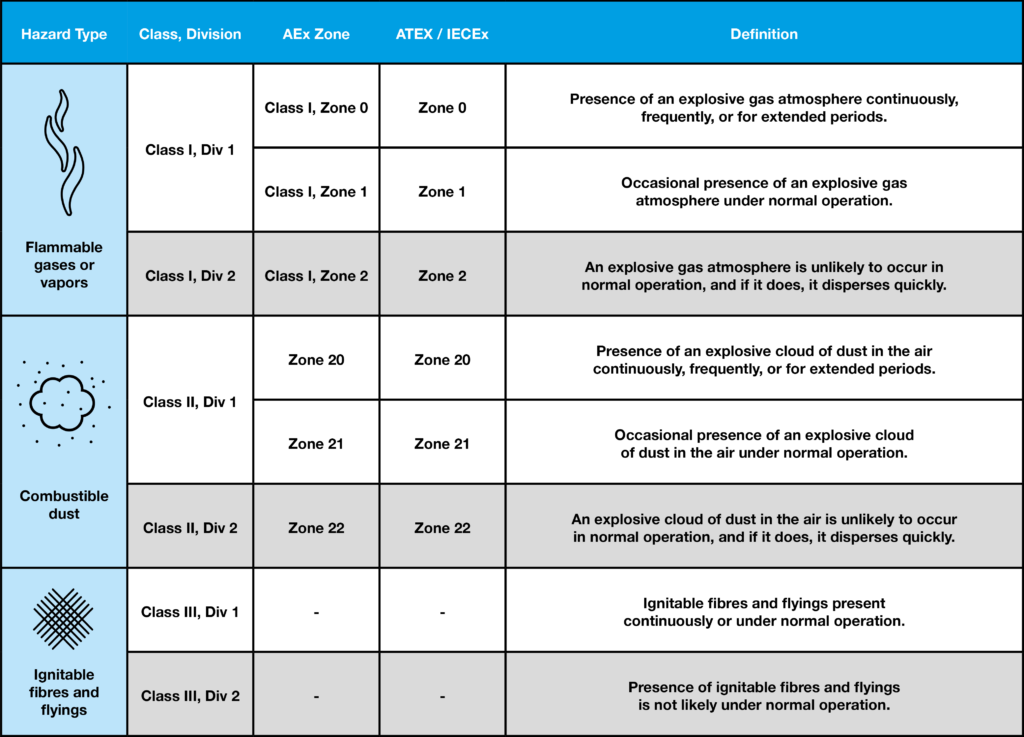

IECEx provides a standardised framework for testing, certifying, and maintaining equipment used in explosive atmospheres. This includes areas where gases, vapors, dust, or fibres might create potentially explosive environments.

Standards and Regulations:

The certification system is based on IEC standards, specifically those related to explosive atmospheres, such as the IEC 60079 series. These standards cover various aspects of equipment safety, including design, testing, installation, and maintenance.

Global Recognition:

IECEx certification is recognised and accepted worldwide, facilitating international trade and ensuring that equipment meets high safety standards across different countries and regions.

Why do industries need ATEX?

Industries need ATEX certification and compliance to ensure safety and mitigate the risks associated with explosive atmospheres.

Here are several key reasons why ATEX is crucial for industries:

- Safety of Personnel:

- Prevention of Explosions: ATEX regulations help prevent explosions that can occur in hazardous environments. This is crucial in industries where flammable gases, vapors, or dust are present.

- Protection of Workers: Ensuring that equipment and installations comply with ATEX standards protects workers from potential hazards and reduces the risk of injury or fatalities.

- Legal and Regulatory Compliance:

- Mandatory Compliance: In the European Union, ATEX compliance is a legal requirement for companies operating in potentially explosive atmospheres. Non-compliance can result in legal penalties, fines, and operational shutdowns.

- Insurance Requirements: Many insurance companies require ATEX certification as a condition for coverage. Non-compliance can lead to higher premiums or denial of coverage.

- Operational Continuity:

- Minimising Downtime: Properly certified equipment is less likely to fail, reducing the risk of downtime due to explosions or other related incidents. This ensures smoother and more reliable operations.