There are many references to IP ratings and their meaning, on the web and within test procedures in standards documents around the globe. This short document is supplemental, to what is already freely available, as a guide to the applicability for antennas and RF Cable connectors.

IP Rating means – ‘Ingress Protection Rating’ and applies to both solids and liquids. The first number deals with different sizes of solid, from hands & fingers to fine powder dust. The second number deals with liquids, pressure and angle of flow through to complete submersion.

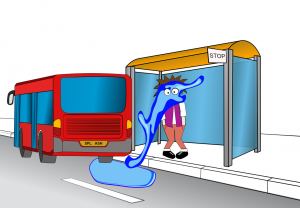

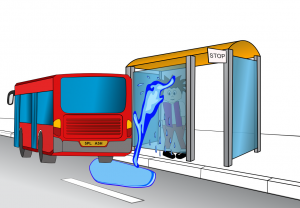

Implementation is as important as the component parts.

|

|

| ok design with poor implementation | good design and implementation |

|

Starting with connectors it is important to note that they are impossible to test to the letter of the test procedure for IP6x (dust imgress) as the test calls for introducing a vacuum using a connection piece which has an M5 thread which is as big as the connector itself. Connections are best kept out of the rain unless specifically designed to provide protection. Many RF connectors contain small sealing washers that keep the water out but vibrations can loosen the connection leaving them vulnerable. |

IP67 is typically tested by performing the water submersion test for 30 mins. If no water gets in then the ‘assumption’ is that no dust will get in either. |

|

|

|

|

Simple solutions to keep them dry can be used; like mounting them under other parts or horizontal placement to keep the worst of the water away. Other possible solutions are to mount them in a watertight box or request longer tails on the antenna so the connections can be passed through a wall to an interior connection point. |

|

|

When considering antennas, there are assumptions that IP67 is better than IP65 or IP66, but a water jet could potentially defeat a seal where a simple submersion test passes. Think about the actual application and location of the antenna in use. If the antenna will only be exposed to rain water then IP65 is sufficient. Over specifying component parts just adds cost to the end product. Additional component costs add to the standard price of your product and once it is in the sales or distribution channel that component cost will have increased significantly. |

This could be the difference between your product being purchased or passed over for a cheaper competitive product. Surface materials of devices can also affect the performance of seals, especially where the surface is curved or has a raised pattern which results in different pressures around or under the seal. Where there is any doubt, test the performance of the combined products before committing to production volumes. |

|

|

|

Curved surface leaves gaps on the sides and uneven pressure |

Patterned surfaces could leave micro gaps for water to flow with uneven pad pressure |

|

The following table highlights the IP ratings number format. IP (or “Ingress Protection”) ratings are defined in international standard EN 60529 (British BS EN 60529:1992, European IEC 60509:1989). They are used to define levels of sealing effectiveness of electrical enclosures against intrusion from foreign bodies (tools, dirt etc) and moisture. The numbers that follow IP each have a specific meaning. First Digit (intrusion protection) – The first digit indicates the degree of protection (for people) from moving parts, as well as the protection of enclosed equipment from foreign bodies entering the enclosure. Second Digit (moisture protection) – The second digit defines the protection level that the enclosure has from various forms of moisture ingress (drips, sprays, submersion etc). In both cases the higher the number the greater the level of protection that is provided. |

|

IP Rating Summary |

|||

|

Rating |

Solids |

Liquids |

|

|

0 |

None |

None |

|

|

1 |

Body parts greater than 50mm |

Dripping water |

|

|

2 |

Body parts greater than 12.5mm e.g fingers |

Dripping water at 15° |

|

|

3 |

Tools and thick wires >2.5mm |

Light spraying water 2 directions 90° different |

|

|

4 |

Wires, screws and insects >1mm |

Splashing water any direction |

|

|

5 |

Some dust ingress allowed but not affecting product performance or function. |

Water jets any direction 4.4psi |

|

|

6 |

No ingress of dust. Vacuum MUST be applied 8 hour test |

Water jets any direction 15psi |

|

|

6k |

– |

Water jets any direction 150psi |

|

|

7 |

– |

Immersion in water up to 1m for 30 minutes |

|

|

8 |

– |

Immersion in water between 1m and 3m to manufacturer declared time |

|

|

9 |

– |

Water jets any direction, close range high temp high pressure up to 1450psi |

|

|

|

See the Antenna Selector Tool for details of antenna products and applicable IP ratings certified by a third party laboratory, or call us to discuss your project needs +44 118 976 9000 |